T5500 Pressure Gauge

The Ashcroft® T5500 stainless steel pressure gauge has become an industry standard.

The Ashcroft® T5500 stainless steel pressure gauge has become an industry standard.

The Ashcroft® T6500 stainless steel pressure gauge has become an industry standard.

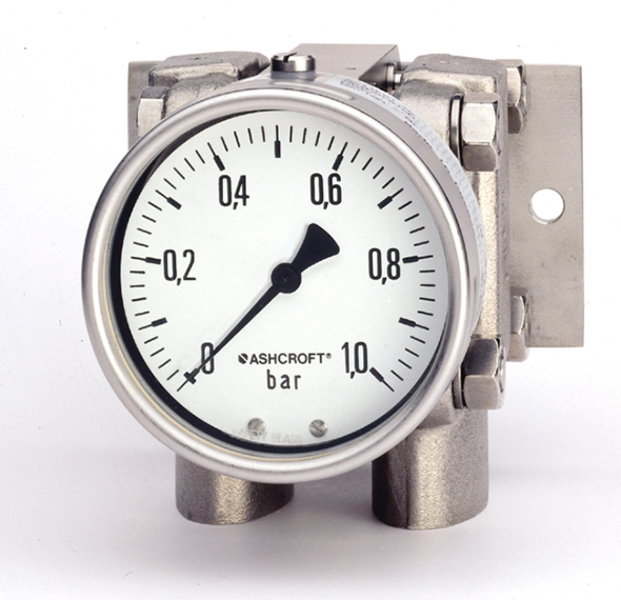

The Ashcroft® F5503 differential pressure gauge is used for monitoring differential pressure between two separate pressure sources.

The Ashcroft® 1259 process gauge is used throughout process and industrial markets, and is known for it’s reliability, safety and performance.

The Ashcroft® 1279 Duragauge® process pressure gauge provides dependability, safety and performance.

The Ashcroft® 1379 Duragauge® process gauge provides dependability, safety and performance.

The Ashcroft® 1377 Duragauge® process gauge provides dependability, safety and performance.

The Ashcroft® 2462 Duragauge® process gauge provides dependability, safety and performance.

The Ashcroft® B4 pressure switch may be used on virtually all industrial and OEM applications.

The Ashcroft® GP pressure switch is used on tough applications requiring a 316L SS enclosure.

The Ashcroft® VP pneumatic pressure switch was designed for use with harsh applications where uncompromising protection is required.

The Ashcroft® B7 NEMA 7/9 pressure switch may be used on virtually all industrial and OEM applications.

The Ashcroft® 1082 test gauge is a precise instrument acclaimed for dependability, safety and performance.

The Ashcroft® Gauge Valve V02-1V isolates the instrument from the process allowing for maintenance and integration.

The Ashcroft® 2 Valve Manifolds V02-2V isolates the instrument from the process and bleeds the assembly allowing for maintenance and integration.

The Ashcroft® Direct & Remote Mount 3 Valve Manifolds-V02 are designed to isolate differential pressure instruments for maintenance and integration purposes.

The Ashcroft® multiport valve V02 isolates up to three instruments from the process allowing for maintenance and integration.

The Ashcroft® Direct & Remote Mount 5 Valve Manifolds-V02 are designed to isolate, bleed and equalize process in differential pressure instruments for maintenance and integration purposes.

The Ashcroft® pressure limiting valve-PL02 protects the instrument assembly from severe pressure spikes.

The Ashcroft® pressure limiting valve-PL01 protects the low pressure instrument assembly from severe pressure spikes.

The Ashcroft® PD02 pressure snubber is used for protecting measurement instruments from sudden pressure increases or fluctuations.

The Ashcroft® cooling devive is direct mounted to the process or inbetween instrument and diaphragm seal, protects instruments from elevated process temperature.

The Ashcroft® flushing ring is providing flushing connection for flush flanged or sandwich type diaphragm seals.

The Swivel Gauge Adapters enable the easy positioning of the pressure instrument in any direction through 360°.

The Ashcroft® threaded thermowells are utilized when pressure, high velocity and corrosive process media exist. This serves to isolate and protect the sensing instrument, and permits removal of a sensing instrument without shutting down the process.

The Ashcroft® flanged thermowell is used when pressure, high velocity and corrosive process media exist. This serves to isolate and protect the sensing instrument, and permits removal of a sensing instrument without shutting down the process.

The Ashcroft® socket weld thermowell is used when pressure, high velocity and corrosive process media exist. Serving to isolate and protect, it also allows the sensing instrument to be removed without requiring process shut down.

The Ashcroft® Van Stone thermowell is used when pressure, high velocity and corrosive process media exist. Designed to mate between two existing flanges.

The Ashcroft® weld-in thermowell is used when pressure, high temperature, high velocity and corrosive process media exist.

The Ashcroft® DF flush flanged diaphragm seal uses a flush diaphragm welded directly to the assembly flange, eliminating the need for a bulky lower housing.

The Ashcroft® DF flush flanged diaphragm seal uses a flush diaphragm welded directly to the assembly flange, eliminating the need for a bulky lower housing.

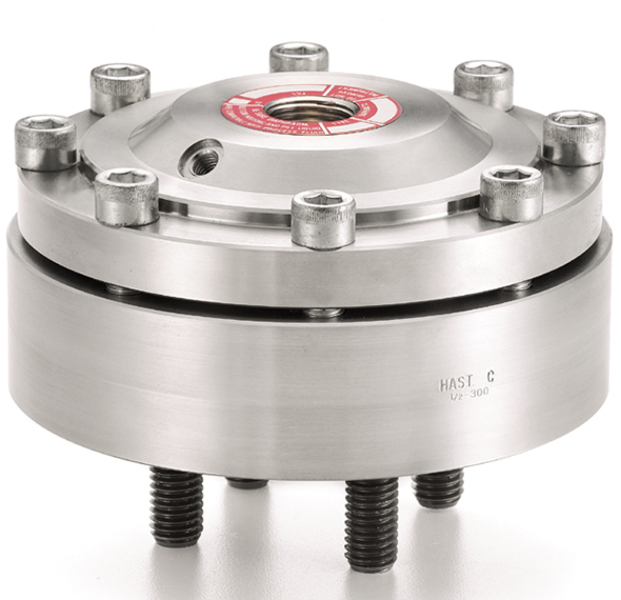

The Ashcroft® 510 and 511 compact, all-welded diaphragm seals or isolation devices protect pressure measuring instruments.

The Ashcroft® 702 and 703 high-displacement diaphragm seals or isolation devices are used with low pressure or differential pressure gauges with low differential pressure and elevated static pressure.

The Ashcroft® 740 and 741 high-displacement diaphragm seals or isolation devices are used with low-ranged instruments or high static pressure dp gauges with low differential pressure.

The Ashcroft® high pressure ball valve-V02 provides systems with a quick, safety shutoff to isolate the process from the instrument assembly during shutdown and maintenance periods.

Acid Leak Detection (ALD) Assembly has a special yellow coating that changes to red once it is exposed to acids with a pH of ≤ 3, providing visual indication of a leak of process media.

The Ashcroft® T6500 stainless steel pressure gauge has become an industry standard.

Vortex thermowells isolate and protect a temperature instrument’s sensing element from pressurized, high velocity and corrosive media. They are used when standard Flanged Thermowells cannot pass ASME PTC 19.3 TW-2016. The helical Strake is designed by using Computational Fluid Dynamic analysis. They ensure longer life and accurate measurement while allowing the sensing instrument to be removed without shutting down the process. A wide selection of materials, sizes and dimensions are available.

Select your Region!