T5500 Pressure Gauge

The Ashcroft® T5500 stainless steel pressure gauge has become an industry standard.

The Ashcroft® T5500 stainless steel pressure gauge has become an industry standard.

The Ashcroft® T6500 stainless steel pressure gauge has become an industry standard.

The Ashcroft® F5503 differential pressure gauge is used for monitoring differential pressure between two separate pressure sources.

The Ashcroft® F5509 differential pressure gauge is used for monitoring differential pressure between two separate pressure sources.

The Ashcroft® F5511 differential pressure gauge is used for monitoring differential pressure between two separate pressure sources.

The Ashcroft® N5500 capsule pressure gauge has become an industry standard for low pressures.

The Ashcroft® P5500/P6500 stainless steel diaphragm pressure gauge has become an industry standard.

The Ashcroft® 1259 process gauge is used throughout process and industrial markets, and is known for it’s reliability, safety and performance.

The Ashcroft® 1279 Duragauge® process pressure gauge provides dependability, safety and performance.

The Ashcroft® 1379 Duragauge® process gauge provides dependability, safety and performance.

The Ashcroft® 1377 Duragauge® process gauge provides dependability, safety and performance.

The Ashcroft® 2462 Duragauge® process gauge provides dependability, safety and performance.

The Ashcroft® APA and APS watertight miniature pressure switches are designed for pressure control in harsh applications.

The Ashcroft® APA and APS explosion proof miniature pressure switches are used for pressure control within harsh applications.

The Ashcroft® B4 pressure switch may be used on virtually all industrial and OEM applications.

The Ashcroft® VP pneumatic pressure switch was designed for use with harsh applications where uncompromising protection is required.

The Ashcroft® B7 NEMA 7/9 pressure switch may be used on virtually all industrial and OEM applications.

The Ashcroft® D4 Differential Pressure switch is designed for use on most applications requiring reliability and long-cycle life.

The Ashcroft® D7 NEMA 7/9 differential pressure switch is designed for applications requiring safety, reliability and long-cycle life.

The Ashcroft® VD pneumatic differential pressure switch was designed for use with harsh applications where uncompromising protection is required

The Ashcroft® T4 Temperature Switch is designed for use on virtually all OEM and Industrial applications.

The Ashcroft® T7 Explosion Proof Temperature Switch is designed for use on many hazardous applications.

The Ashcroft® VT pneumatic temperature switch was designed for use with harsh applications where uncompromising protection is required

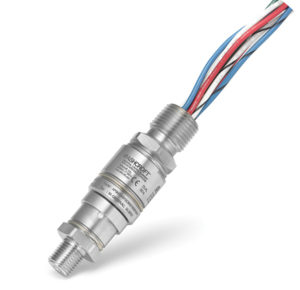

The Ashcroft® A2 industrial pressure transmitter is designed to satisfy the requirements of industrial applications.

The Ashcroft® A2X pressure transmitter fulfills a wide spectrum of pressure sensing requirements when explosion and flame-proof hazardous location ratings are needed.

The Ashcroft® ATE-2 handheld calibrator is an exceptional instrument performing precision measurement of pressure, temperature, current or voltage.

The Ashcroft® S5500 gas actuated thermometer is a direct or remote mounted instrument providing performance while being highly resistant to shock and vibration.

The Ashcroft® C-600A-01 Duratemp® thermometer is a remote mounted instrument providing performance while being highly resistant to shock and vibration.

The Ashcroft® C-600B Duratemp® thermometer is a direct-mount instrument providing performance while being highly resistant to shock and vibration.

The Ashcroft AR10 RTD provides a reliable means for monitoring and controlling temperature.

The Ashcroft AR20 RTD delivers a reliable method for monitoring and controlling temperature.

The Ashcroft AT10 Thermocouple provides a reliable means for monitoring and controlling temperature.

The Ashcroft AT20 Thermocouple delivers a reliable method for monitoring and controlling temperature.

The Ashcroft AT30 Skin Type Thermocouple offers a reliable and economical solution for monitoring process temperature without the use of a thermowell.

The Ashcroft® Gauge Valve V02-1V isolates the instrument from the process allowing for maintenance and integration.

The Ashcroft® 2 Valve Manifolds V02-2V isolates the instrument from the process and bleeds the assembly allowing for maintenance and integration.

The Ashcroft® Direct & Remote Mount 3 Valve Manifolds-V02 are designed to isolate differential pressure instruments for maintenance and integration purposes.

The Ashcroft® multiport valve V02 isolates up to three instruments from the process allowing for maintenance and integration.

The Ashcroft® Direct & Remote Mount 5 Valve Manifolds-V02 are designed to isolate, bleed and equalize process in differential pressure instruments for maintenance and integration purposes.

The Ashcroft® pressure limiting valve-PL02 protects the instrument assembly from severe pressure spikes.

The Ashcroft® pressure limiting valve-PL01 protects the low pressure instrument assembly from severe pressure spikes.

The Ashcroft® PD02 pressure snubber is used for protecting measurement instruments from sudden pressure increases or fluctuations.

The Ashcroft® 1115A and 1115P capillary lines are utilized when instruments need to be removed from direct contact with the installation point due to elevated process temperature, pressure spikes or design specifications.

The Ashcroft® cooling devive is direct mounted to the process or inbetween instrument and diaphragm seal, protects instruments from elevated process temperature.

The Ashcroft® flushing ring is providing flushing connection for flush flanged or sandwich type diaphragm seals.

The brackets are designed for panel, wall and 2″ pipe mounting and give full clearance for ease of handle operation.

Straight Pipes and 90° Elbows are used when gauge syphons are not necessary due to the service conditions.

The Swivel Gauge Adapters enable the easy positioning of the pressure instrument in any direction through 360°.

The Ashcroft® threaded thermowells are utilized when pressure, high velocity and corrosive process media exist. This serves to isolate and protect the sensing instrument, and permits removal of a sensing instrument without shutting down the process.

The Ashcroft® flanged thermowell is used when pressure, high velocity and corrosive process media exist. This serves to isolate and protect the sensing instrument, and permits removal of a sensing instrument without shutting down the process.

The Ashcroft® socket weld thermowell is used when pressure, high velocity and corrosive process media exist. Serving to isolate and protect, it also allows the sensing instrument to be removed without requiring process shut down.

The Ashcroft® Van Stone thermowell is used when pressure, high velocity and corrosive process media exist. Designed to mate between two existing flanges.

The Ashcroft® weld-in thermowell is used when pressure, high temperature, high velocity and corrosive process media exist.

The Ashcroft® DF flush flanged diaphragm seal uses a flush diaphragm welded directly to the assembly flange, eliminating the need for a bulky lower housing.

The Ashcroft® DF flush flanged diaphragm seal uses a flush diaphragm welded directly to the assembly flange, eliminating the need for a bulky lower housing.

The Ashcroft® 510 and 511 compact, all-welded diaphragm seals or isolation devices protect pressure measuring instruments.

The Ashcroft® 702 and 703 high-displacement diaphragm seals or isolation devices are used with low pressure or differential pressure gauges with low differential pressure and elevated static pressure.

The Ashcroft® 740 and 741 high-displacement diaphragm seals or isolation devices are used with low-ranged instruments or high static pressure dp gauges with low differential pressure.

The Ashcroft® truncated flanged diaphragm seal model DT protects pressure measuring instruments on isolated pipes or tanks.

The Ashcroft® truncated flanged diaphragm seal model DT protects pressure measuring instruments on isolated pipes or tanks.

The Ashcroft® model A bimetallic thermometer provides high quality and performance.

The Ashcroft® EI bimetallic thermometer provides high quality and performance.

The Gauge Valve DIN 16272 Type A isolates the instrument from the process and bleeds the assembly allowing for maintenance and integration.

Calibration according to DAkkS or in-house standards including certificate and calibration sticker

We check and repair all ASHCROFT® and HEISE® pressure and temperature measurement devices.

A new product test center has been completed at the Ashcroft Inc. world headquarters in Stratford, Connecticut. The facility has been outfitted with a host of specialized test equipment to simulate virtually any adverse operating condition that an Ashcroft® product may Encounter while in service.

The Ashcroft® 2198 MicroTube Siphon protects pressure instruments from the effects of elevated temperatures.

The Ashcroft® low pressure ball valve-V02 is designed to quickly and safely isolate the process.

The Ashcroft® high pressure ball valve-V02 provides systems with a quick, safety shutoff to isolate the process from the instrument assembly during shutdown and maintenance periods.

Acid Leak Detection (ALD) Assembly has a special yellow coating that changes to red once it is exposed to acids with a pH of ≤ 3, providing visual indication of a leak of process media.

The Ashcroft® T6500 stainless steel pressure gauge has become an industry standard.

The Ashcroft® E2G general industrial pressure transducer is the optimal choice for a rugged, precise and repeatable solution for measurement requirements that are needed on a wide array of applications.

ASHCROFT® Platinum Series Process Pressure Transmitters are used worldwide for continuous data Acquisition in the oil & gas, chemical, power, water and waste water industries.

ASHCROFT® Gold Series Process Pressure Transmitters are used worldwide for continuous data Acquisition in the oil & gas, chemical, power, water and waste water industries.

ASHCROFT® Silver Series Process Pressure Transmitters are used worldwide for continuous data Acquisition in the oil & gas, chemical, power, water and waste water industries.

ASHCROFT® Bronze Series Process Pressure Transmitters are used worldwide for continuous data Acquisition in the oil & gas, chemical, power, water and waste water industries.

ASHCROFT® Platinum Series Differential Process Pressure Transmitters are used worldwide for continuous data Acquisition in the oil & gas, chemical, power, water and waste water industries.

The PRESSISION sensor is the result of our relentless pursuit of development and innovation and surpasses everything that has gone before.

Our diaphragm seals and diaphragm seal systems are the result of our many years of development work and application experience. In dialogue with our customers, we develop application and user-specific solutions.

The Ashcroft 8008S delivers the advanced features of a larger gauge in a small, economical package for applications requiring an all stainless steel instrument for harsh environments.

The Ashcroft® E2S pressure transducer fulfills a wide spectrum of pressure sensing requirements when intrinsically safe or non-Incendive hazardous approvals are required.

The Ashcroft® E2X and E2F pressure transducers fulfills a wide spectrum of pressure sensing requirements when explosion or flameproof hazardous approvals are required.

The Ashcroft® 331 all-welded flush mini-diaphragm seal or isolation device protect pressure measuring instruments.

The Ashcroft® level switch series LS is designed to measure liquid levels in both unpressurised and pressurised tanks.

The Ashcroft® T6500 stainless steel pressure gauge has become an industry standard.

Vortex thermowells isolate and protect a temperature instrument’s sensing element from pressurized, high velocity and corrosive media. They are used when standard Flanged Thermowells cannot pass ASME PTC 19.3 TW-2016. The helical Strake is designed by using Computational Fluid Dynamic analysis. They ensure longer life and accurate measurement while allowing the sensing instrument to be removed without shutting down the process. A wide selection of materials, sizes and dimensions are available.

Select your Region!